Advantages of using GGBS include lower CO 2 emissions, a substantial reduction of environmental impacts and an increased scope for sustainability due to the higher PC replacement levels that are permitted for GGBS. FA does still considerably improve sustainability when compared to PC, but this work proved that inclusion of GGBS environmentally optimises the mix design even further. With respect to optimum mix design, it is strongly recommended that GGBS is selected as the addition of choice for reducing CO 2 emissions. Results show that Mix 2 (CEM II/B-V) and Mix 3 (CEM III/B) could potentially be taken forwards to improve their environmental impacts of concrete production.

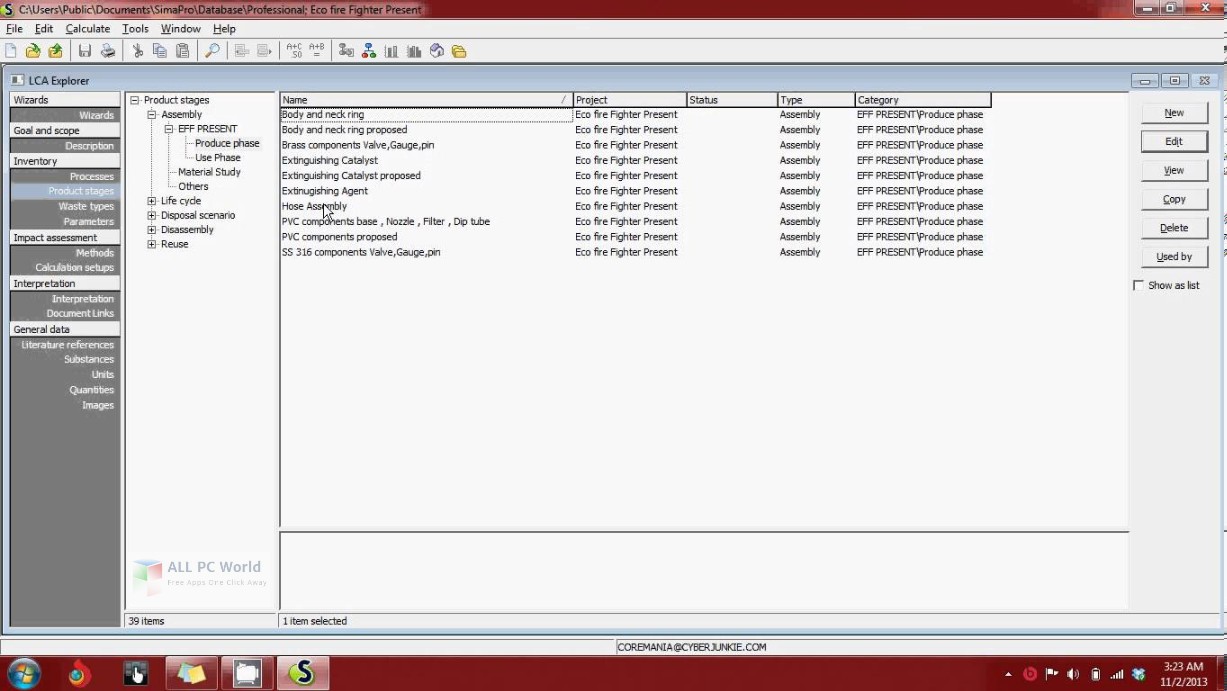

Recommendations from this work would help the industry make key decisions about concrete mix designs. A comparative cradle-to-gate LCA of these mixes has not currently been explored and could present a new insight into improving the environmental impact of concrete with the use of secondary materials. Evaluations of the three concrete mixes were performed using ‘SimaPro 8’ LCA software. The aim of this study was to obtain the overall environmental impact, with a particular focus on carbon dioxide (CO 2) emissions of three concrete mix designs: CEM I (100 % PC content), CEM II/B-V (65 % PC content, 35 % Fly Ash (FA) content) and CEM III/B (30 % PC content, 70 % ground granulated blast furnace slag (GGBS) content). This study intended to carry out a ‘cradle-to-gate’ life cycle assessment (LCA) on concrete mix designs containing different cementitious blends.

This has led to ‘greener’ cementitious materials being developed which can decrease the use of traditional Portland cement (PC). The concrete industry faces challenges to create concrete mix designs that reduce negative environmental impacts but also maintain high performance.

0 kommentar(er)

0 kommentar(er)